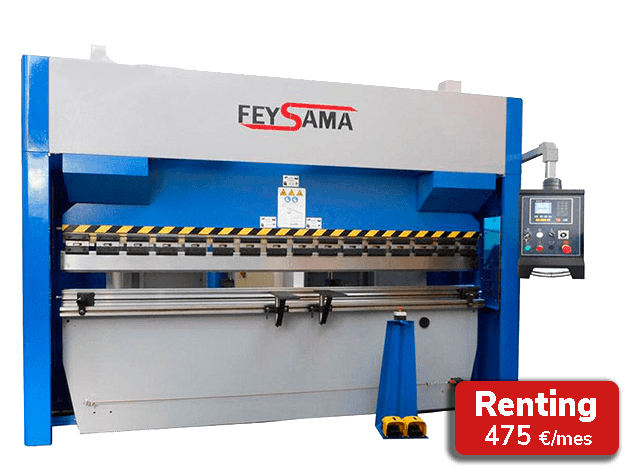

Technical features

- Axle Positioner NC (X, Y) 40 Programs

- Manual crowning by wedges in the beam./li>

- Manual awl anchorage

- Compulsory photocells according to CE12622 of 900mm.

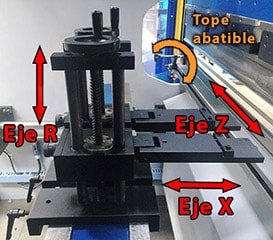

- Manual R and Z axis, adjustable fom the backside

- Backside speed stop (Axis X) 65 mm/s

- Ball screw and chromed bar

- Backside stop 600mm

- Deepth of goove to 350mm.

- 1 Year warranty for manufacturing defects.

- SAT Free telephone service for life.

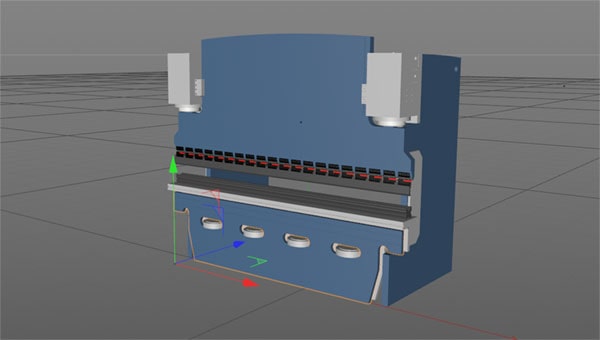

Standard equipment

Axle Positioner 40 Programs

The positioner, which allows the automatic movement of the folding machine axes, consists of a memory of 40 programs (pieces) with 25 steps (folds).

It allows to work manually, step by step or automatically, that is, when a fold is finished, the positioner will move the 2 axes to perform the next fold automatically.

Simple operation like a calculator, you enter the measurement and by pressing the green button the axes move to the desired measurement.

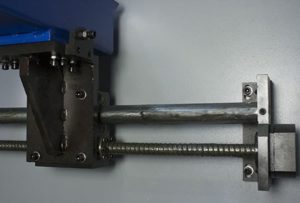

Manual crowning with GONIOMETER

The crowing goniometer allows the X position of the turret to be precisely adjusted and the hinged stop prevents the sheet from getting caught when it is lifted when bent. The R (height) and Z (width) axes can also be adjusted manually.

The stop turrets move on a sturdy machined bar that can be adjusted in pregnancy and provides precision, not like aluminum bars that, being weaker, can be bent or twisted.

Translated with www.DeepL.com/Translator (free version)

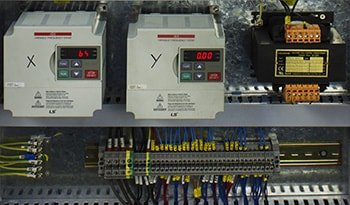

DOUBLE SPEED AND Compulsory photocells

Para cumplir la norma CE12622 obligatoria para el plegado de chapa si se quiere trabajar con doble velocidad (rápida y lenta) o una velocidad de descenso superior a los 10mm/s se debe incorporar una fotocélulas de seguridad, de más de 800mm de alto, en la parte frontal, con el objetivo deparar la bajada rápida de la trancha en el caso de que algo atraviese la zona protegida.

Nuestras máquinas incorporan de serie una fotocélula de 900mm de alto, de la firma italiana Datalogic, que nos permite utilizar la velocidad rápida de descenso (80-100mm/s) reduciendo considerablemente los tiempos de plegado.

Esta fotocélula está monitorizada por el PLC de seguridad Pilz para evitar que un falloen ella provoque una situación de peligro, parando la máquina antes de que esto ocurra.

Equipo opcional

CNC S625 NUMÉRICO PROGRAMABLE A GRADOS

Este CNC permite programar piezas mediante grados, ya que el propio CNC calcula la medida en la que obtendremos el plegado deseado en la chapa de acuerdo al punzón, la matriz, el espesor de la chapa que queremos doblar etc…

Incluye una protección para no dañar los útiles que se pueden seleccionar de una librería en el control. Incorpora un puerto USB que facilita la comunicación con un PC sin necesidad de cables y permitiendo así tener una librería de útiles y programas infinita. Permite gestionar hasta 3 ejes.

Software 2D para PC de oficina técnica gratuito, permite el cálculo automático de la secuencia de plegado y realizar listas de tareas para organizar el trabajo.

ANCLAJE RÁPIDO DE PUNZONES

El anclaje rápido permite substituir los punzones de una forma rápida sin necesidad de herramientas, tan solo aflojando manualmente las palancas rojas, el punzón se descuelga sin caer, para que pueda ser arrastrado hasta sacarlo por el lateral.

Accesorio ideal para los plegados de bandejas y cajas en los que el operario tiene que estar cambiando de punzón continuamente ya que reduce el tiempo del cambio.

Además entre las grapas ofrecen mayor apertura para aquellas cajas que tienen un ala grande.

CNC S630 PROGRAMABLE A GRADOS 2D

Este CNC permite dibujar las piezas en 2D mediante grados, y probar la secuencia de plegado, con lo que no necesitamos hacer numerosas pruebas con chapa en la plegadora hasta encontrar la medida correcta para doblar a los grados que queremos. Al finalizar, el CNC nos dará el desarrollo de la chapa y el cálculo de la presión de trabajo

Incluye una protección para no dañar los útiles que se pueden dibujar o seleccionar de una libreria en el control. Incorpora un puerto USB que facilita la comunicación con un PC sin necesidad de cables y permitiendo así tener una librería de útiles y programas infinita. Permite gestionar hasta 4 ejes. Opcionalmente puede realizarse telediagnóstico.

Software 2D para PC de oficina técnica gratuito, permite el cálculo automático de la secuencia de plegado y realizar listas de tareas para organizar el trabajo.

Opcionalmente se puede incorporar teleasistencia.

¿Tienes alguna consulta?

Llámanos y te ayudaremos a escoger la plegadora que más se adapta a tus necesidades.

Así como seleccionar los accesorios más adecuados para tu tipo de trabajo.

Solicite presupuesto a medida